Making Hay While the Sun Shines with Jeni Kardinal

As an architect, I’ve been interested in sustainable building strategies for a long time, and have been particularly interested in the benefits of straw bales. Over the years I’ve visited several straw bale homes in the United States and New Zealand, and after coming to Bali and seeing all the rice paddies my interest was rekindled. There was plenty of waste straw available and it didn’t seem anyone in Bali was using it. Not having baling machines made it a bit harder and there was the question of making bales in a humid climate – was it going to be possible?

We began testing a few small sample bales at home here in Bali, checking the moisture levels over a period of several years to see if they met building code standards. To our delight, the readings met the code requirements so at that point I felt it would be possible to build in a humid climate. But it was still difficult to find someone to invest in a pilot project. It wasn’t until I spoke with my uncle in Florida who suggested bringing the idea to his Rotary Club in Tarpon Springs that interest was sparked. Within a year, and with the Tarpon Springs, Holiday, Dunedin North and Dunedin clubs sponsoring along with Bali Taman here, which I belong to, Rotary had enough money to build the first straw bale building in Bali – an education project to teach locals in the remote village of Nawa Kerti how to build sustainably.

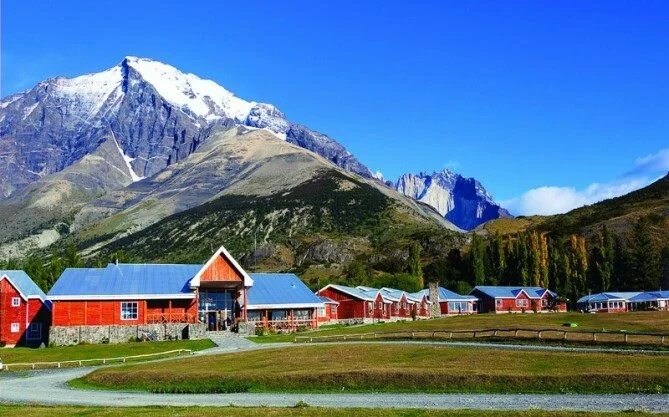

There were two reasons to choose this site for the pilot project. First, it was in a relatively dry area in Karangasem, East Bali where the rains didn’t start until December which gave us a few additional months of dry weather to get the bales made and walls built, which helped considering we started the foundations the end of September! Secondly, we had a good relationship with Kadek Suardan from the village of Nawa Kerti. Kadek’s

Making Hay While the Sun Shines with Jeni Kardinal enthusiasm for the project began early on with the testing of bales, well before the project was funded. His leadership skills really made a big difference to working remotely with the locals in the village and was key in the success of the project.

Before making the bales, Kadek collected straw from nearby rice paddies and brought it to the village to dry in an open field. It’s critical that the straw be dry before putting it into bales! With dry straw, it only takes about 10 minutes to make a bale and our building needed 70 full bales and 12 half bales. The walls are pinned externally with bamboo stakes and tied between courses with twine. The first course of bales are set onto rebar spikes that are set into the concrete and the foundation is wide enough for the bales and set 50cm off the ground to keep the bales out of the splash zone from rain, and then we used three coats of earth plaster. Making a straw bale building in Indonesia takes a few more steps than your typical straw bale building in the West as you have to make the bales manually! We designed a bale press using available wood and plywood, that can be taken apart and transported from site to site easily. Our press can make both a 50 x 50 x 100cm, or two half bales of 50 x 50 x 50cm. (There is a 6:1 height to width ratio so a 50 cm wide bale can create a wall that’s three metres high.)

Since we make our own presses, it can be designed to be any shape or size, but for the first building we chose a conventional size. I would like to try a curved bale press in the next building and experiment with other shapes as well. We used bamboo for the wall pinning, roof framing, bathroom structure and bale post. The system for treating the bamboo uses a small pressure tank filled with water, borax, boric acid and a bit of food colouring.

The Three Little Pigs have given building with straw a bad rap, and surprising to many, bale buildings have been fire tested in labs and have been given a one-hour fire rating within the U.S. building codes. They are even more difficult to burn after a coat of earth plaster. Other misconception is that bugs and rats will eat it. Rice straw is high in silica and low in nutrition making it undesirable to bugs and rats, because all the nutrition is in the seed.

Some of the benefits to using straw bales are that they are super insulated making them ideal for cool as well as warm climates (the building we created is very cool inside without any air-conditioning); sound absorbent (ideal for home theatres, schools, spas, recording studios, music rooms etc.)… and they are good in earthquakes, making them an ideal building material for use in Indonesia.

The total building cost including the bale press, bamboo treatment system, the bathroom structure, covered patios, and straw bale building (4 x 7 metres) = US$ 14,500.

The solution was pressurized through the bamboo instead of soaking. This system is much faster and a 4-metre piece of green bamboo can be treated in about 10 – 15 minutes. We could see the food colouring at the end to know the solution went through the entire piece. This system was created in Costa Rica in 2001 and we wanted to try it here in Bali. Bamboo is very sustainable and lightweight. With a light roof, we didn’t need to add any structural columns within the straw walls, thus keeping the structure simple and less costly. The finished roof is alang alang thatch so the entire building is essentially made from various species of grasses. What could be more sustainable?

It’s really important to use earth plasters and not cement-based stuccos for the wall finish as earth and clay plasters keep the straw dry by wicking the moisture out of the straw. Cement plaster can trap moisture in the walls and cause problems, whereas arth plasters breath and are more ecological. We used clay from Karangasam mixed with volcanic sand and soil from the site with chopped straw fibres and rice husks. We also added a solution we made using the slime from chopped cactus that helps the plasters elasticity and water resistance.

When the building is finished it will be used as a small factory for making cold pressed virgin coconut oil, which will be available for market soon, with 100% of the proceeds going directly to the village. There is a big need for

quality cold-pressed coconut oil for use in spas and I knew the village had an abundance of coconut trees so I just put 2 and 2 together. Kadek and the others in the village were eager to learn how to improve the way they made coconut oil to a cold pressed system, which increases the value, making it more profitable for the people in the village. Once the production is in full swing, they will start to develop relationships with spas and other businesses locally.

The people in the village are so proud to have built the first straw bale building in Bali, and perhaps in Indonesia. They have learned the skills of how to treat bamboo efficiently and the entire process of how to build a straw bale building. With that knowledge, they can go on to create other buildings for themselves and the team can be hired to build for others. Over time it would be great to see the knowledge spread from village to village.I would really like to continue helping teach the locals and others how to build using straw bales and we plan to create a bilingual manual and DVD that can help ensure successful projects. There are a few important steps to take when building with straw bales and getting the information out to others through the manual and workshops could really help foster the idea.Overall, it would be fantastic to see more straw bale buildings in Bali, leading to a “grass” roots movement throughout Indonesia creating jobs and futures for people in sustainable building.